Our Key Projects

Learn more about our key projects that we've been successful with.

Our Key Projects

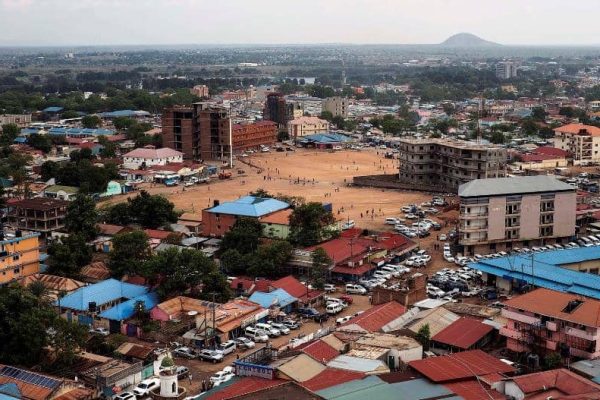

Kenya

1. Mombasa Sewerage Project & Changamwe Sewage Treatment Works

2. Tana Delta Irrigation Project

3. Villa Franca Housing Estate Roads, Nairobi

4. Swahili Culture Project – Gedi National Monument

5. Salt Works Infrastructure, Kurawa, Malindi

South Sudan

1. Bor Maternity Hospital (WHO)

2. Juba Logistics Base (WFP)

3. Yirol Vocational Training Centre (NPA)

4. Hamza Hotel, Juba

5. State Ministry Offices, Bor & Rumbek (UNOPS)

Somalia

1. Multipurpose Facilities, Mogadishu (UNSOA/AMISOM)

2. Construction of Hardwall Defensive Facilities, Somalia (various subcontracts – ongoing) Includes hardwall accommodation and office units, reinforced concrete bunkers, Reinforced Concrete Overhead Protection Structures (OHP), Pre-detonation layer Roof Structures, HESCO and concrete barriers.

Niaz Engineering Key Projects

1. Construction of Pre-Detonation Layers at UNSOS Facilities, Somalia

| Project Title: | Construction of Pre-Detonation Layers over Existing Building Structures at UNSOS Facilities, Mogadishu |

|---|---|

| Client | UNSOS – United Nations Support Office Somalia |

| Location | Mogadishu, Somalia |

| Year | 2025 |

| Role | Main Contractor |

| Project Purpose | Design and construction of pre-detonation shielding layers over 35 existing overhead protection (OHP) structures and existing buildings at the UN FHQ camp in Mogadishu, Somalia. The project aimed to enhance defensive resilience by adding an upper sacrificial layer above existing Reinforced Concrete OHP slabs to absorb the impact of mortar shelling and indirect blasts impact. |

| Scope of work: | • Structural assessment and coordination for integration with existing OHP roofs; • Fabrication and installation of treated timber trusses and framework; • Installation of marine plywood boards to form continuous shielding surfaces; • Fixing of CI sheeting for upper roof coverage and protection; • Construction of braced perimeter plywood panels as side shielding; • Rainwater management via installation of gutter systems and downpipes; • Execution carried out directly above operational UN facilities with strict safety coordination; • Works delivered in line with UNSOS defensive infrastructure specifications. |

| Challenges | The roof installation had to be executed in a confined compound with no access for mechanical lifting equipment. All materials, including long trusses and roofing sheets, had to be manually handled and installed on narrow elevated surfaces, making alignment, movement, and safety particularly challenging |

| Our Solution | A temporary intermediate platform was constructed at mid-height to enable safe and efficient manual lifting of timber trusses, plywood, and roof sheets. Materials were passed up in coordinated sequences by the crew, and all works were completed on the rooftop under tight spatial constraints. Strict safety protocols, including use of harnesses, edge awareness, and staged progression, ensured smooth delivery despite the restricted environment. |

2. UNGU Safe Training Site – Reinforced Concrete Overhead Protection (OHP) Structures

| Project Title | Construction of Overhead Protection (OHP) Structures at the UNGU Safe Training Site in Mogadishu |

|---|---|

| Client | UNSOS – United Nations Support Office Somalia |

| Location | Mogadishu, Somalia |

| Year | 2024 |

| Role | Main Contractor |

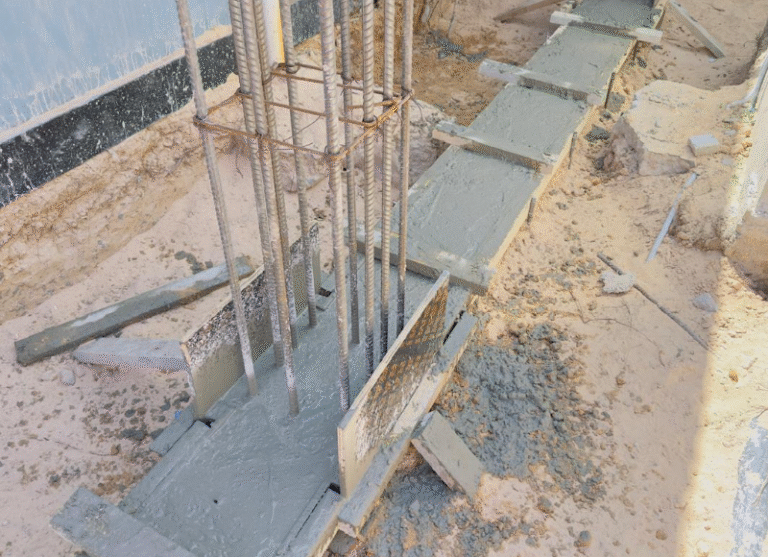

| Project purpose | Design and construction of Reinforced Concrete Overhead Protection structures at the UNGU (United Nations Guard Unit) Safe Training Site in Mogadishu, Somalia. The project involved the erection of densely reinforced protective concrete canopies over existing prefabricated units to enhance personnel safety against mortar and indirect blast impact. |

| Scope of works | • Site investigation and engineering design of structural elements. • Excavation, foundation construction, and RCC column casting. • Shuttering, reinforcement, and casting of overhead protective slabs above live prefab units. • Construction of Pre-detonation layer timber truss roofing. • Installation of HESCO barriers along blast-facing sides of the building. • Construction works carried out in phases to ensure safe access and minimal disruption to ongoing UN operations. • Compliance with UN safety, operational, and defensive infrastructure standards. |

| Challenges: | Executing overhead RCC works above vacated prefab units under compound-wide operational constraints. Customizing soffit formwork systems without anchoring to or loading on existing prefab structures. The need to span wide areas with reinforced slabs while avoiding contact with sensitive UN facilities below created formwork and access planning challenges. Rebar congestion added further difficulty in controlling form vibrational stability during pouring. |

| Our Solution: | We developed independent staging using modular scaffold towers, allowing controlled casting above cleared units while maintaining compound access for other missions. Formwork was installed in phases with rapid strike mechanisms to support sequential shifts. |

3. Overhead Protection (OHP) Structures within UN compound facilities in Somalia.

| Project Title: | Construction of Various Overhead Protection (OHP) Structures within UN compound facilities in Somalia. |

|---|---|

| Client | UNSOS – United Nations Support Office Somalia |

| Location | Mogadishu, Beledweyne - Somalia |

| Year | 2021-2024 |

| Role | Main Contractor |

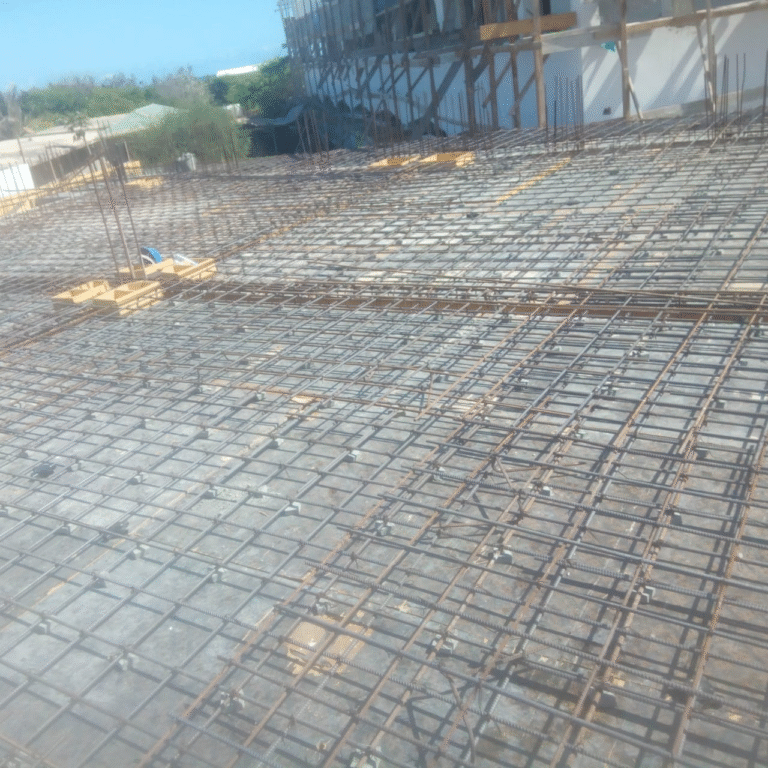

| Project purpose | Design and construction of more than 25 Reinforced Concrete Overhead Protection (OHP) Structures at various UN facilities in Somalia, commissioned by UNSOS. These structures were purpose-built as defensive protective roofs to shield existing prefabricated accommodation and operational units from mortar shelling and indirect blast threats, in line with UN security engineering protocols. Each OHP structure was designed to absorb and deflect blast energy from above, comprising heavily reinforced concrete slabs supported by columns and beams. |

| Scope of works | • Structural design according to protective engineering standards for blast/mortar resistance; • Site layout, excavation, and concrete substructure works around live UN facilities; • Reinforcement detailing and dense rebar mesh for high-impact load resistance; • Specialized formwork and propping to avoid overloading existing prefab units; • Concrete pouring (cast-in-situ) with high-strength mix for slab and beam elements; • Waterproofing, surface finishing, and structural integration with existing prefab modules; • Installation of solar heaters, utility access points, and protective coatings; • Executed in a phased manner to maintain UN operational continuity and strict adherence to HSE/security protocols. |

| Challenges | Executing overhead RCC works over vacated UN structures within a live compound, requiring carefully staged sequencing and non-invasive soffit formwork systems to avoid damage or disruption to surrounding operations. Traditional soffit formwork could not be used, as direct support on or through the existing prefabricated structures was prohibited. The high reinforcement density and slab span demanded a temporary works solution that ensured stability, load distribution, and safety. |

| Our solution | We engineered a suspended and cantilevered soffit formwork system using free-standing scaffold towers and custom bracing frames to transfer loads safely to the ground. This allowed safe slab pouring without touching the structures below and enabled fast phased works aligned with operational clearances. |

4. Construction of National Independent Electoral Compound (NIEC) Warehouse and Reinforced Concrete Facilities

| Project Title | Construction of National Independent Electoral Compound (NIEC) Warehouse and Reinforced Concrete Facilities |

|---|---|

| Client | UNSOS |

| Location | Mogadishu, Somalia |

| Year | 2020 |

| Role | Main Contractor |

| Project purpose | To support Somalia’s national electoral readiness by constructing a secure, blast resistant reinforced concrete warehouse and utility facility within the National Independent Electoral Commission (NIEC) compound. The project provided purpose-built infrastructure for material storage, operational coordination, and secure logistics, enabling long-term support for electoral missions under the United Nations. |

| Scope of works | • Construction of a reinforced concrete warehouse structure • Delivery of additional RC service blocks and facility rooms • Full MEP installation (HVAC, electrical, water, lighting) • Stormwater drainage, compound grading, and access roads • Architectural plastering, painting, and finishes (internal and external) • Blockwork walls, lintels, and roofing • Reinforced concrete retaining walls |

| Challenges | Located outside the secure UN compound, requiring daily security clearance and logistical coordination to stay on schedule under restricted access. Furthermore, Tight compound corridors made it difficult to manage heavy equipment and overlapping trades. Simultaneous RC and MEP works required strict sequencing. |

| Our Solution | Works were executed in parallel zones; preassembled MEP items minimized on-site time. Deliveries and crew movements were pre-scheduled within low-traffic access windows, maintaining safety and timeline integrity. |

5. Multi-purpose Hard-Wall Offices and Accommodation facility at Phase 7A and 7B at UNSOS Compound

| Project Title | Construction of Multi-purpose Hard-Wall Offices and Accommodation facility at Phase 7A and 7B at UNSOS Facility in Mogadishu |

|---|---|

| Client | UNSOS |

| Location | Mogadishu, Somalia |

| Year | 2015-2017 |

| Role | Main Contractor |

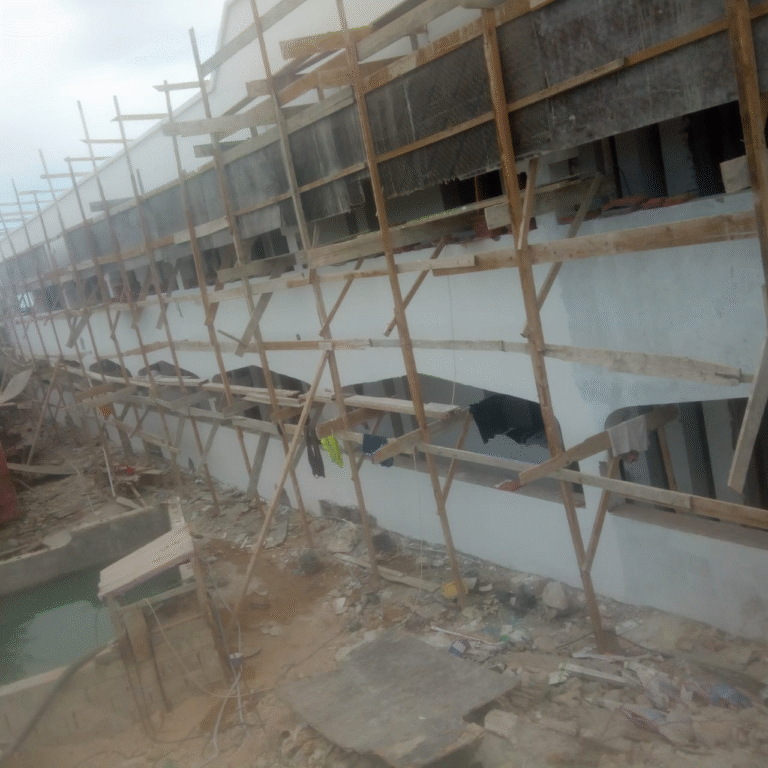

| Project purpose | Design and Construction of a Hard Wall Multi-Purpose Office Building, Accommodation Facilities, and Underground Tunnel Crossing, executed under UNSOS Phase 7A and 7B in Mogadishu, Somalia. The project involved complete turnkey delivery, beginning with detailed architectural, structural, mechanical, and electrical designs and continuing through full civil and MEP execution. |

| Scope of works | • Site clearance, topographic survey, and bulk excavation. • Reinforced concrete works for foundations, slabs, columns, beams, and roofs. • Construction of two multi-storey hard-wall buildings and a tunnel structure with retaining walls. • Complete electrical systems including panels, cabling, lights, sockets, and backup provisions. • HVAC installations across office and accommodation spaces. • Sanitary and plumbing systems include internal piping, water tanks, and connections. • Architectural finishes include plastering, painting, windows, tiling, and ceiling works. • Tunnel crossing and underground infrastructure for secure movement between zones. • Site works: security fencing, concrete pathways, drainage, and auxiliary service structures. |

| Challenges | Construction of an underground walkway tunnel in constrained site conditions connecting multiple secure zones. Simultaneous execution of multi-storey vertical RC works and deep excavation under tight security protocols. Tunnel Works involved hard excavation through coral rock, water ingress control, and uninterrupted site logistics. Structural tie-in between the tunnel and adjacent buildings required high precision. |

| Our solution | Tunnel works were carried out in controlled stages, using mechanical chiseling to break through coral rock. Dewatering pumps managed groundwater inflows during excavation. Activities were carefully sequenced to avoid interference with simultaneous vertical RC works above. Structural tie-ins to adjacent buildings were pre-marked and aligned using on-site templates, ensuring precision. Secure logistics routes were maintained throughout, with strict access timing and close coordination with security teams. |

6. Construction of Phase 9 Hard-Wall Accommodation Facility at UNSOS Compound

| Project title | Construction of Phase 9 (9A, 9B, 9C) Hard-Wall Accommodation Facility at UNSOS Compound |

|---|---|

| Client | UNSOS |

| Location | UNSOS |

| Year | 2018-2020 |

| Role | Main Contrcator |

| Project purpose | Design and Construction of three reinforced concrete (RC) hard-wall accommodation buildings (Blocks 9a, 9b, and 9c) within Phase 9 of the UNSOS Camp, Mogadishu, Somalia. The project was delivered as a turnkey contract, starting with architectural, structural, mechanical, and electrical design development based on UNSOS functional requirements and performance specifications. |

| Scope of works | The scope included full construction delivery—site clearing, grading, foundation casting, vertical and horizontal RC works, block walling, and roofing. Building services involved: • Electrical: design and installation of 50 distribution panels (main/sub), lighting, small power, and integration into the Building Management System (BMS); • Mechanical (HVAC): design and installation of 30 heating/cooling units, ductwork, and climate control systems; • Plumbing & Drainage: full system layout and installation including potable water, wastewater, and fittings; • Waterproofing & Roof Insulation: application of membrane systems and thermal protection; • Finishes: full internal fit-out including flooring, plastering, ceilings, and paintwork; • Security & ICT: provisions for access control and communication cabling; • External civil works including paving, service access paths, and drainage channels. All works were executed in compliance with international construction standards and UNSOS health, safety, and operational requirements. |

| Challenges | Coordinating full architectural and MEP execution within an active camp environment. Managing logistics for sequential phased delivery without material storage space or crew congestion. Multiple buildings required simultaneous structural, electrical, and HVAC installation under tight timeline constraints. Coordinating underground and wall-embedded services alongside structural works required tight planning. |

| Our solution | We adopted a modular execution plan, assigning distinct crew rotations to foundation, structural, and finishing works. Materials were delivered in controlled batches and integrated with on-site prefab storage. Early coordination with the UN on panel locations enabled smooth commissioning of HVAC and plumbing. |

7. Construction of a reinforced concrete two-storey Recreation Facility (T Block) at the UNSOS compound.

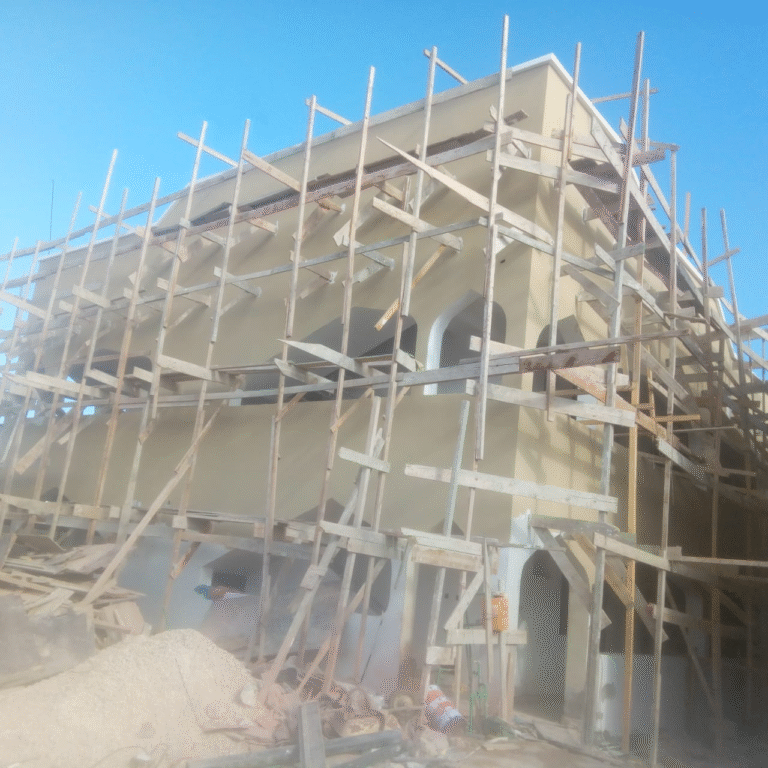

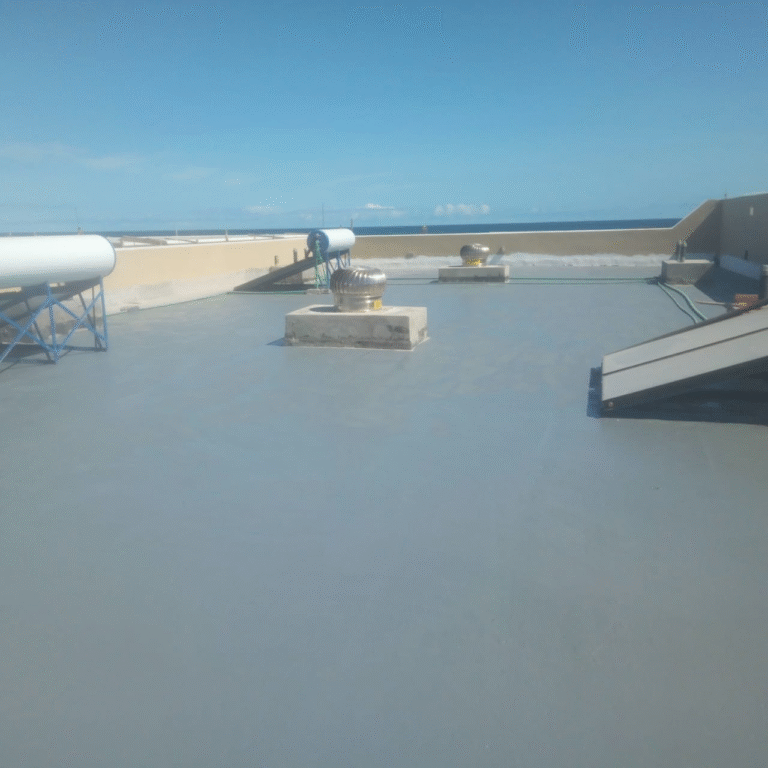

| Project title | Construction of a reinforced concrete two-storey Recreation Facility (T Block) at the UNSOS compound. |

|---|---|

| Client | UNSOS |

| Location | Mogadishu, Somalia |

| Year | 2014-2015 |

| Role | Main Contractor |

| Project purpose | Design and Construction of a reinforced concrete two-storey Recreation Facility (T Block) at the UNSOS compound in Mogadishu, Somalia. The project was delivered as a turnkey contract and included complete architectural, structural, mechanical, and electrical design and execution. |

| Scope of works | The scope of work involved: • Site clearing, excavation, and foundation construction. • Full RC structural frame including slabs, beams, columns, and staircases. • Hollow block masonry, internal and external plastering. • Electrical installation including lighting, small power, switchboards, and air conditioning. • Mechanical work includes plumbing, drainage, sanitary fittings, and solar water heating system. • Interior finishes: tile flooring, ceilings, paintwork, doors, and windows. • External work includes paved circulation areas, stormwater drainage, and boundary connections. • Delivery of rooftop service structures, access ladders, and waterproofed tiled terraces. • Compliance with all UN safety, quality, and operational standards. The facility was designed to host recreational and communal functions for UN staff and was delivered within time and budget. |

| Challenges | Full architectural, structural, and services delivery within a fixed 12-month schedule in a high-security compound. The reinforced concrete frame required high formwork turnover within limited staging zones. MEP coordination for solar heating, drainage, and internal finishes demanded precise trade sequencing. |

| Our Solution | We adopted a tightly phased schedule using high-efficiency formwork systems and parallel MEP fit-out teams. External works and rooftop installations were executed concurrently with internal finishes to meet the delivery target under UN operational constraints. |